Al-Sc alloys application in semicon industry

Reasons to add scandium

Aluminum scandium alloy (AlSc) has recently gained significant interest in the semiconductor industry as a material used in high-performance components. With scandium content reaching up to 30% by weight, AlSc offers unique physical and chemical characteristics that make it an excellent choice for various electronic applications.

The addition of scandium significantly alters the properties of aluminum, enhancing its strength, hardness, ductility, and resistance to corrosion and fatigue. AlSc's unique combination of material properties makes it ideal for meeting the rigorous demands of the semiconductor industry.

Semicon applications of Al-Sc alloy

One of the most extensive applications of AlSc in semiconductors is in the manufacturing of interconnects for integrated circuits (ICs). Integrated circuits are complex devices that require multiple connecting wires to pass signals efficiently; these connecting wires must handle a current density well beyond the rest of the metal network. AlSc demonstrates excellent mechanical and electrical properties that make it an ideal candidate for interconnects that require such high current densities. Furthermore, interconnects made from AlSc exhibit higher conductivity, which leads to lower power dissipation and heat generation inside IC chips.

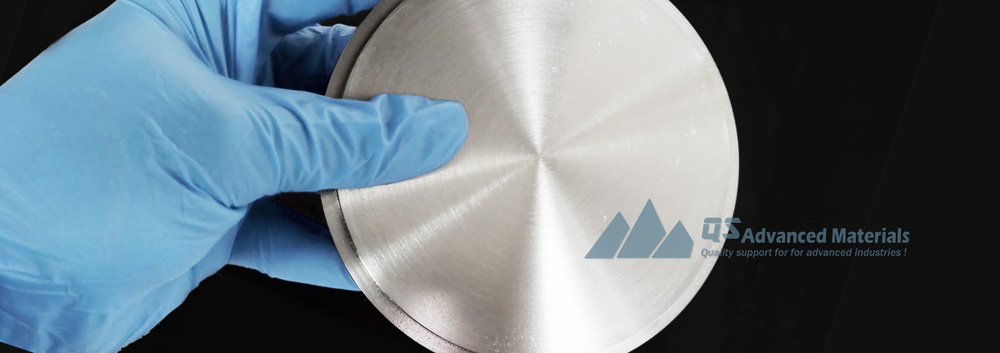

Moreover, AlSc shows minimal electromigration failure rates in uniform line width test structures, compared to copper and other nickel-free alloys. Understanding this reliability failure mechanism is critical for guaranteeing a predictable life cycle, considering the shrinking of modern circuit geometries, placing more pressure on alternative materials capable of replacing traditional materials like copper. Sputtering technique is usually applied to deposite aluminum scandium on the silicon wafer. AlSc sputter target is the cusumption of this process.

Another application of AlSc in the semiconductor industry is the manufacture of power devices. Power devices handle high electric currents and voltage levels, hence requiring materials that exhibit high thermal conductivity and good electrical conductivity properties; AlSc’s high specific heat, thermal conductivity, and low resistivity make it an excellent base generator material drawing attention from researchers using this material. Using AlSc in power devices helps improve circuit performance, reduce device size, and dissipate heat effectively.

In addition, AlSc’s unique combination of properties also makes it suitable for the production of heat sinks and cold plates used in cooling electronic devices. As compared to traditional aluminum alloys, AlSc has superior thermal conductivity, allowing better heat dissipation from hot spots. This improved heat dissipation leads to better performance and an extended lifespan of electronic components.

Other applications of Al-Sc alloy

The benefits of AlSc extend beyond ICs, power devices, heat sinks, and cold plates. The growing demand for high-performance materials has driven researchers to explore other potential applications of AlSc, which include optoelectronics, microwave communications, and sensors. The goal is to create new and innovative electronic products with improved performance that meet the ever-increasing demands of current technology.

For instance, AlSc shows promise in fiber optic communication systems as a material used to manufacture optical connectors, fiber splices, pluggable transceiver modules, and other components required in data transmission. Its high strength, durability, low weight, and low attenuation coefficient help maintain signal quality over long distances.

Moreover, Semiconductors and packaging supporting standard or high-frequency bias offer outcomes when technical advances are coupled with proper analysis of industry requirements. Due to its ability to withstand corrosion and fatigue, AlSc can be an appropriate choice for electronic, structural, and packaging applications used in 5G networks through enhancements often mature into new levels of effective performance.

Conclusion

AlSc is increasingly becoming a popular material in the semiconductor industry due to its unique physical and mechanical properties, which make it an excellent choice for a wide range of electronic applications. The incorporation of scandium into aluminum drastically alters its fundamental characteristics by adding excellent electrical conductivity, ductility, corrosion resistance, and high thermal conductivity; however, the higher scandium content generates additional cost challenges. Advancements in manufacturing processes will continue making exploration exploring the benefits of AlSc more cost-effective, driving its implementation towards various applications. Nevertheless, AlSc’s use could propel technological innovation forward and boost electronic device performance, durability and, contribute to further advances in smart technology.