Significant Enhancement of CdZnTe Crystal Quality through Novel Techniques: Innovative Research by a Spanish Team

Recent Developments

Researchers V. Carcelén and N. Vijayan, along with their team from the Universidad Autónoma de Madrid (Autonomous University of Madrid) in Spain, have published a notable research paper in the Journal of Optoelectronics and Advanced Materials. Titled "New approaches in order to enlarge the grain size of bulk CdZnTe (CZT) crystals," this work details their innovative techniques that have significantly improved the grain size and overall quality of CdZnTe crystals.

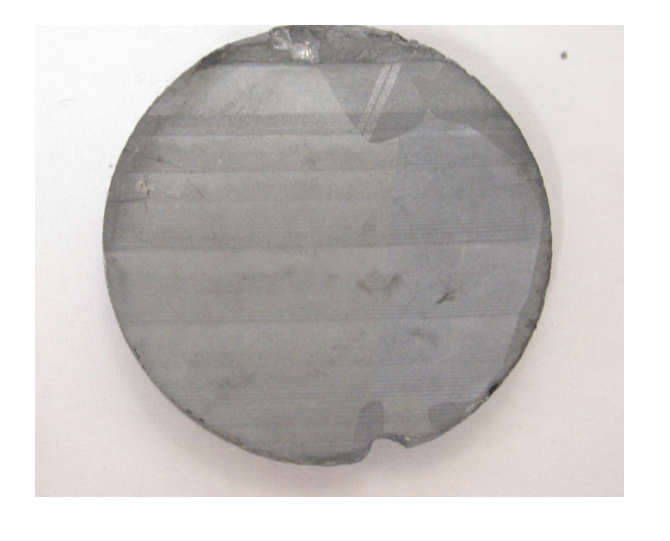

Importance and Challenges of CZT Crystals

CZT (Cadmium Zinc Telluride) is a II-VI compound semiconductor that finds widespread applications in X-ray and gamma-ray detectors, medical imaging, security screening, and space exploration. Despite the promising prospects of CZT crystals, their production process faces multiple challenges, such as improving crystal quality, reducing tellurium inclusions, and increasing grain size.

Oscillating Bridgman (OBR) Method and Superheating Conditions

The research team employed the Oscillating Bridgman technique and a superheating approach, which effectively promoted the fragmentation of tellurium inclusions and significantly increased the grain size of the CZT crystals.

Bridgman Process Improvement with Pt Tube

By using a Pt tube as the cold finger in the Bridgman furnace, the team improved the thermal environment during the crystal growth process. This modification significantly altered the temperature gradient, reduced the radial heat flow, and subsequently enhanced the crystal growth rate and grain size.

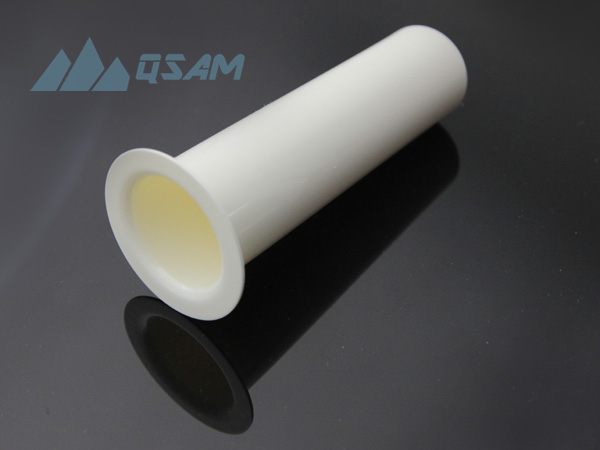

Bridgman Growth from the Vapor Phase Using PBN Crucibles

The researchers utilized PBN (pyrolytic boron nitride) crucibles in their Bridgman setup, which are highly pure and thermally stable. The use of these crucibles, along with specific temperature profiles, promoted the growth of CZT crystals, particularly the crystallization from the vapor phase, effectively improving the quality and uniformity of the crystals.

QSAM Inc., the leading manufacturer of PBN crucibles in the market, provides high-quality crucibles to support the experimental needs of researchers. Their professional manufacturing capabilities and customized services ensure that researchers can obtain the most suitable crucibles for their specific experimental requirements, thus driving the progress of scientific research.

PBN Crucible

Impact of Magnetic Field Growth under Microgravity

During the FOTON M3 mission, the researchers applied a Rotating Magnetic Field (RMF) prior to crystal growth, which reduced the tellurium clusters in the melt and improved the structural quality and grain size of the crystals.

CZT Growth with Borosilicate Encapsulation

By adding borosilicate particles in a quartz crucible and performing encapsulation, the team successfully prevented material evaporation and interactions between the crystal and the crucible.

Research Outcomes and Impact

The study by the Spanish research team has significantly improved the growth quality and grain size of CZT crystals, providing important technical support for further enhancing the performance of X-ray and gamma-ray detectors. These advancements can improve the uniformity and resolution of detectors, while also contributing to cost reduction and the commercialization of related technologies.

Improved Detector Performance

The enhanced crystal quality and larger grain sizes can substantially improve the response uniformity and resolution of detectors to X-rays and gamma-rays, which is crucial for medical imaging (such as CT scans), nuclear security screening, and space exploration applications.

Cost Reduction and Commercialization Driving

The optimization of crystal growth techniques also helps to reduce production costs. Larger grain sizes mean more efficient material utilization and lower waste during the manufacturing process, which is key for the commercial deployment of CZT crystals and their corresponding detectors.

Implications for Technological Innovation

This research not only provides a significant technical breakthrough in materials science but also offers new perspectives for the growth of other semiconductor materials. Similar techniques may be applicable to improving the growth processes of silicon, gallium arsenide, and other semiconductor materials.

Future Outlook

While the research team has already achieved remarkable results, they plan to continue optimizing the growth parameters and techniques to further enhance the crystal quality and yield. Additionally, they intend to apply these technologies to other types of semiconductor materials, exploring their potential in various application domains.

Conclusion

The research team from the Universidad Autónoma de Madrid has made important advancements in enhancing the quality and grain size of CZT crystals. These technological developments not only contribute to the progress in the related fields but also open up new possibilities for a wide range of scientific and industrial applications. As further research and development continue, these high-performance semiconductor materials are expected to exhibit even greater application potential in diverse areas.