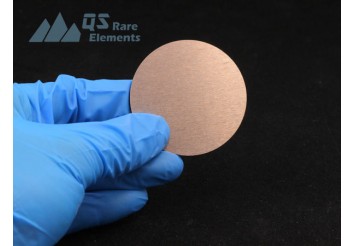

Copper Tungsten(Cu-W) sputter target

Composition:Copper, Tungsten(Cu,W)

Catalog No.:RF7429-ST

Purity:99.95%

Typical Lead Time:4 weeks

- Product Details

Tungsten copper target introduction

Tungsten Copper (W-Cu) is a composite material composed of tungsten (W) and copper (Cu). It combines the high melting point and hardness of tungsten with the excellent thermal conductivity of copper. Tungsten copper exhibits high melting point and hardness along with good thermal conductivity. When used as a sputter target in the electronics industry, W-Cu is commonly employed for packaging and electrode materials. Due to its thermal expansion coefficient similar to materials such as silicon, silicone, and ceramics, tungsten copper is frequently utilized in electronic packaging. Additionally, its high wear resistance and electrical conductivity make it suitable for electrode components in electron tubes and high-frequency devices, providing stable current transfer and high-temperature resistance.

QSAMs copper tungsten products

As a composite material rather than a true alloy, W-Cu cannot be produced using conventional melting furnaces due to tungsten's extremely high melting point. At QSAM, our W-Cu sputter targets are typically fabricated via powder metallurgy methods. This involves mixing tungsten and copper powders followed by sintering at high temperature and pressure to achieve a dense, homogeneous target material. QS Advanced Materials can supply both tungsten copper and silver tungsten sputtering targets in a variety of shapes to meet research and production needs. As a premier provider of tungsten composite materials, QSAM is always ready to receive inquiries from customers. We welcome custom target design opportunities and encourage potential clients to reach out with their specifications and drawings. Our applications laboratory is well-equipped to assist with design, prototyping and testing of non-standard sputter targets.

Common composition of copper-Tungsten alloy

|

Composition wt. % |

Density g/cm3 |

Hardness HB Kgf/mm2 |

Resistivity micro Ome*cm |

IACS% |

Bending strengthMpa |

|

W50/Cu50 |

11.85 |

115 |

3.2 |

54 |

- |

|

W55/Cu45 |

12.3 |

125 |

3.5 |

49 |

- |

|

W60/Cu40 |

12.75 |

140 |

3.7 |

47 |

- |

|

W65/Cu35 |

13.3 |

155 |

3.9 |

44 |

- |

|

W70/Cu30 |

13.8 |

175 |

4.1 |

42 |

790 |

|

W75/Cu25 |

14.5 |

195 |

4.5 |

38 |

885 |

|

W80/Cu20 |

15.15 |

220 |

5 |

34 |

980 |

|

W85/Cu15 |

15.9 |

240 |

5.7 |

30 |

1080 |

|

W90/Cu10 |

16.75 |

260 |

6.5 |

27 |

1160 |

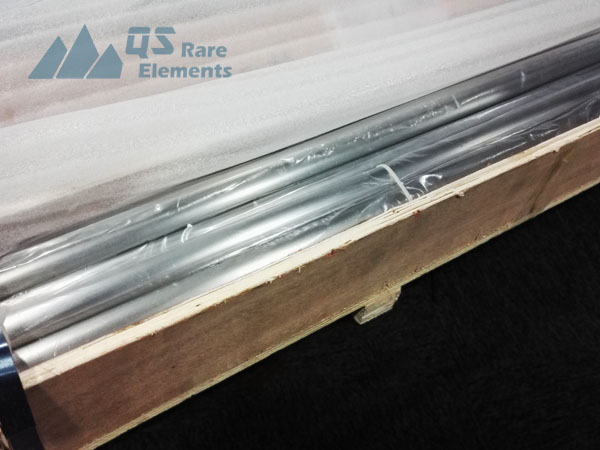

Tungsten copper packaging

Tungsten copper is stable in air and packed without vacuum seal, unless requested. Wooden crater is applied when the cargo is over weight.

*Mill report available for our tungsten copper sputter target.

Related Product