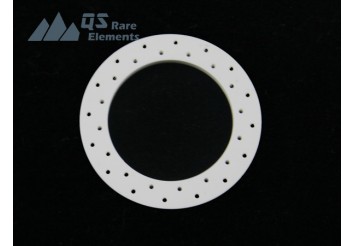

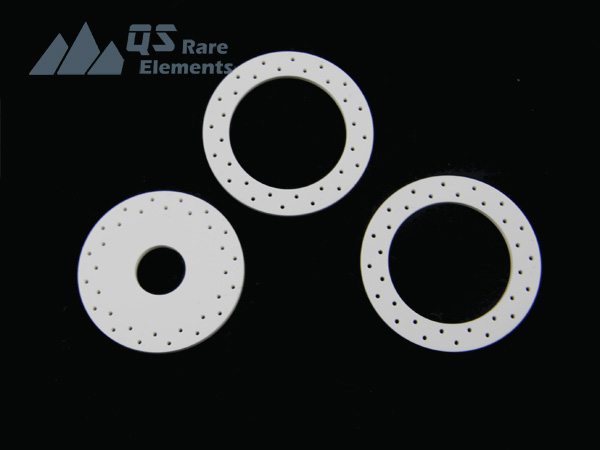

Pyrolytic Boron Nitride Ring | PBN Ring

Material: Pyrolytic Boron Nitride /PBN

Production techinque: CVD

Purity: >99.99%

![]() Chemical content of QSAM PBN crucible

Chemical content of QSAM PBN crucible

![]() Pysical properties of QSAM PBN crucible

Pysical properties of QSAM PBN crucible

- Product Details

Pyrolytic Boron Nitride (PBN) Ring

supplied by QS Advanced Materials is produced by CVD process (chemical vapor deposition) to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, thick wall products (>3mm) is usually not available. PBN is also a good choice for extremely high purity boron nitride. As the purity of gas material (BCl3 + NH3 --> BN +HCl) is a lot higher than regular boron nitride powder, purity for PBN is quite high and 99.99% is the typical grade. With it's high purity, high mechanical strength, high performance with molten metal and salts, PBN is beacaming an widely used material in high vacuum processes. Without showing melting point and high thermal conductivity, pyrolytic material are ideal to be used as vacuum furnace parts.The CVD process give this pyrolytic boron nitride almost perfect layered strucuture, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing.

The pyrolytic boron nitride rings QSAM could supply, are cut from 1mm 2mm or 3mm thick PBN rings with about 10~14" diameter. The diameter of raw material PBN was limited by equipment size but the finished PBN products could be machined to highly customized shape with competitive cost.

Pysical properties of PBN

|

Boron Nitride Content |

99.99% |

|

|

Crystalline |

hexagonal |

|

|

Physical Properties |

Along crystal plane (a) |

Perpendicular crystal plane (c) |

|

Lattice Constant |

2.5x10-10m |

6.8x10-10m |

|

Flexural Strength MPa |

60 |

N.A. |

|

Tensile Strength MPa |

>80 |

N.A. |

|

Density |

2.1 g/cm3 |

|

|

Hardness ~Knoop |

11 kg/mm2 |

|

|

Thermal Conductivity 200C |

82W/mK |

2.6W/mK |

|

Thermal Conductivity 900C |

55.3W/mK |

2.8W/mK |

|

Thermal Expansion RT |

2x10-6/K |

15.5x10-6/K |

|

Dielectric Constant |

5.2 |

3.8 |

|

Dielectric Strength |

59KV/mm |

|

|

Electrical Resistance RT |

>1014ohm cm |

|

PBN Ring Applications

Pyrolytic boron nitride (PBN) rings, manufactured using the chemical vapor deposition (CVD) method, exhibit perfect layered hBN crystals that grow along their surfaces. This unique structure ensures uniform thermal conductivity throughout the ring, distinguishing it from hot-pressed BN or other ceramics. Additionally, the CVD process results in exceptionally high purity levels of PBN, reaching up to 99.99%. These properties make PBN rings an excellent choice for applications such as molecular beam epitaxy (MBE). In MBE equipment, PBN rings are commonly used as support materials for crucibles. The compatibility with PBN crucibles ensures a consistent performance and enables a contamination-free environment for the MBE process. The combination of PBN crucibles and rings provides a reliable and efficient solution for researchers and industries seeking optimal results in MBE applications.

List Of PBN Products QSAM supplies

| PBN Disc/Sheet/Ring |

| PBNMachined Products and Custom Parts |

| PBN Crucibles(VGF/LEC/Conical/MBE) |

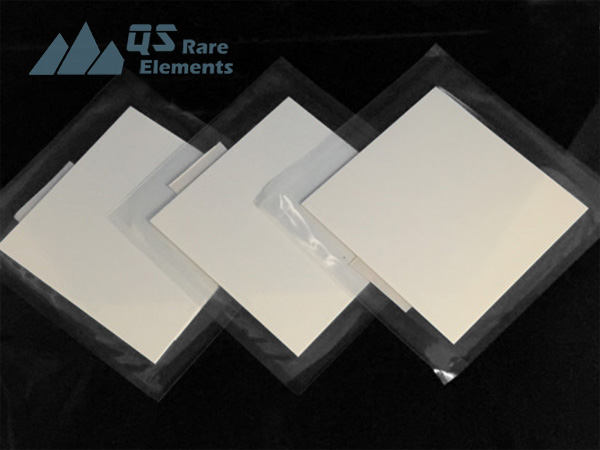

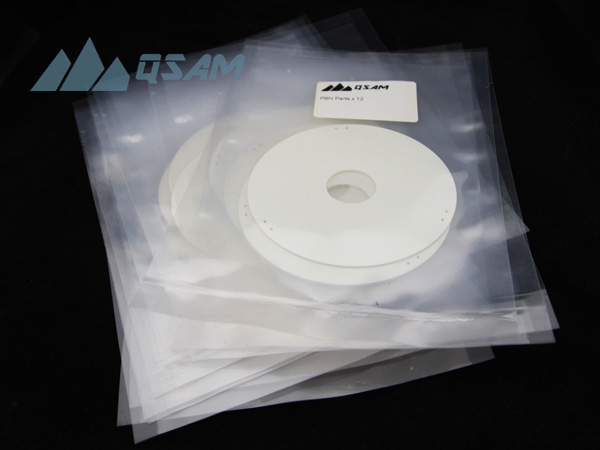

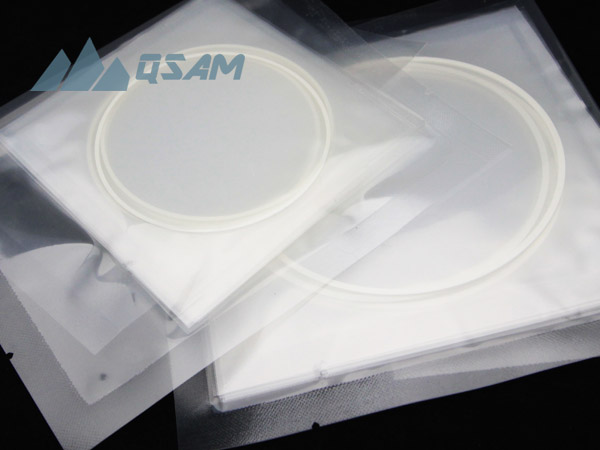

PBN Packaging

As a ceramic material, boron nitride is quite fragile in a lot of cases. The PBN rings are usually hold in plastic bags by vacuum, and protect with heavy foam.