Silicon vs. CIGS: Comparing Thin-Film Solar Panel Technologies

Introduction

As thin-film solar panels gain global popularity, two key technologies - silicon and CIGS - compete for dominance. With unique advantages and limitations, determining the optimal thin-film solution depends on the application. Silicon solar cells provide stable efficiency at low cost, but suffer in high temperatures. Meanwhile, CIGS films offer higher efficiency potential and flexibility, but currently carry higher prices. By comparing critical factors like efficiency, cost, temperature resilience and customizability, consumers can evaluate whether lightweight silicon or robust CIGS better fits their energy needs. Understanding these key trade-offs allows for informed adoption of the best thin-film photovoltaic technology.

Silicon Thin-Film Solar Panels

Silicon thin-film photovoltaics, first created in 1976, pioneered thin-film solar technology. With over 40 years of research, silicon comprises the most established option. Unlike heterojunction CIGS cells, silicon thin films utilize p-i-n or n-i-p junctions with intrinsic semiconductor layers. P-i-n architectures demonstrate higher efficiencies around 10%, though lower than CIGS films. Silicon thin films claim only 2% of the PV market but provide a stable, low-cost option. With improved light absorption and defect passivation, silicon cells continue gaining efficiency. For reliable and affordable solar power, silicon thin films present a proven thin-film solution.

Advantages:

l Proven technology with over 40 years of R&D

l Lower costs than CIGS and other thin films

l Good efficiency around 10%, though lower than CIGS

l Better low light performance than crystalline silicon

l Temperature resistant, performance stable in heat

l Durable panels with long lifetimes over 25 years

l Abundant silicon material, established manufacturing

Disadvantages:

l Lower efficiency potential than CIGS thin films

l Toxic manufacturing byproducts like silicon tetrachloride

l Potential light-induced degradation over time

l Narrower light absorption spectrum than CIGS

l Rigid panels unlike flexible CIGS films

l Smaller market share compared to other technologies

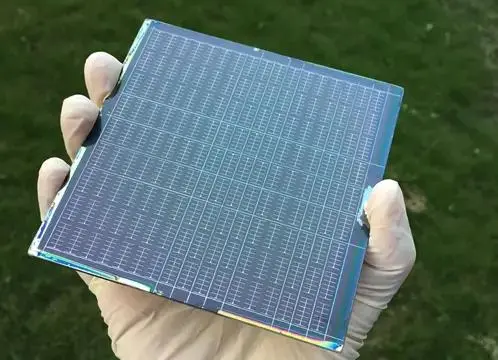

CIGS Thin-Film Solar Panels

CIGS, short for copper indium gallium selenide, emerged in 1995 when National Renewable Energy Lab researchers produced the first CIGS thin film solar cells. One of the three dominant thin film technologies, CIGS cells have demonstrated lab efficiencies reaching 23%, with theoretical potential up to 30% through ongoing enhancements. Unlike silicon-based panels, CIGS maintains performance in low light and cool temperatures. This resilience enables widespread deployment in space applications. On Earth, CIGS flexibility allows integration into curved surfaces on vehicles or buildings. And with light-weight CIGS portable chargers, people can access solar energy anywhere. While CIGS carries higher costs currently, improved manufacturing techniques aim to increase affordability and adoption. With versatile advantages, CIGS thin film photovoltaics will likely continue gaining market share over older technologies like silicon.

Advantages:

l High efficiency potential up to 23% in lab, 30% theoretical

l Low light and low temperature performance

l Flexible, lightweight and customizable panels

l Can be integrated into curved surfaces

l Higher temperature coefficients than silicon

l Long lifetimes of over 20 years

l Low toxicity manufacturing compared to CdTe

l Aesthetic colors and semi-transparent options

Disadvantages:

l CIGS thin-film solar panels are not as widely available as silicon thin-film solar panels.

Similarities

While silicon and CIGS thin-film solar panels utilize different materials, they share common traits that distinguish them from crystalline alternatives. For instance, both thin-film technologies are manufactured through depositing ultra-thin photosensitive layers onto substrates, enabling lightweight and flexible panel designs. Additionally, thin-film fabrication requires far less silicon or CIGS material than bulk crystalline panels. These fundamental similarities make thin-film photovoltaics an efficient, cost-effective solar energy solution.

Silicon and CIGS thin-film photovoltaics share key similarities, including flexibility, lightweight designs, and equal market presence. The thin semiconductor layers make both technologies bendable and adaptable to curved surfaces, unlike rigid crystalline silicon panels. Additionally, the ultra-thin films minimize weight, enabling easy transportation and installation. However, Silicon and CIGS thin films have only captured 2% of solar market share each so far, lagging behind crystalline counterparts. But with continuous improvements in efficiency and cost, thin-film PV adoption is steadily rising.

Differences

While silicon and CIGS thin-film solar cells share common traits, differences in materials, efficiency, cost, and temperature response set them apart. Silicon thin films utilize abundant amorphous silicon whereas CIGS relies on the compound of copper, indium, gallium, and selenium. This leads to divergent temperature coefficients of -0.234%/°C for silicon versus -0.36%/°C for CIGS. Silicon's efficiency peaks around 14% under standard conditions, lagging behind record 23% efficiency for CIGS. Additionally, manufacturing advantages currently provide cheaper $0.69/W costs for silicon compared to $0.60/W for CIGS panels. But with rapidly improving production techniques, CIGS costs are dropping quickly. While silicon offers an affordable solution, CIGS provides higher performance potential. Weighing key factors like cost, efficiency and temperature resilience helps determine the optimal thin film technology for specific solar applications.

Conclusion

Choosing between silicon and CIGS thin-film solar technologies requires weighing key factors like cost, efficiency, flexibility, and application. With higher potential efficiency yet currently higher prices, CIGS excels for specialized usage where performance matters more than budget constraints. Meanwhile, affordable and stable silicon thin films suit more cost-conscious large-scale solar projects. By evaluating unique pros and cons, consumers can determine the optimal thin-film photovoltaics for their specific solar needs.