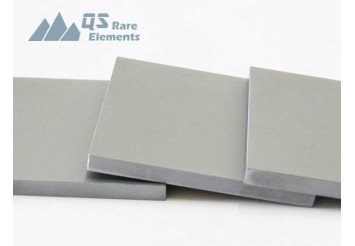

Tantalum (Ta) bar

Formula: Tantalum (Ta, Atomic No. 75)

Catalog No.: RM73-BAR

Purity of unalloyed Ta : 99.95%

Typical lead time: 3 weeks

- Product Details

Tantalum (Ta) bars introduction

At QSAM Inc., we stand out as a supplier of special and rare metals, and we are excited to offer tantalum bars among our products. Tantalum bars are known for their incredible durability, high melting point, and remarkable resistance to corrosion, making them a top choice for various industrial applications.

These bars become go-to materials for the chemical industry because they stand strong against even the most aggressive chemicals. This is crucial for equipment that must operate reliably over long periods in harsh environments. The electronics sector also benefits from our tantalum bars. They are used to build parts like capacitors and resistors, which are essential for stable electronic circuits. conductivity.

The medical and aerospace fields prefer our tantalum bars too. Surgeons trust them for creating biocompatible implants, and aerospace engineers rely on them for parts that can withstand extreme temperatures.

Our tantalum bars

Here at QSAM Inc., we are committed to high standards. We deliver tantalum bars that are both pure and robust, thanks to our cutting-edge production processes. QSAM can supply tantalum material with small MOQ and custom production! Large amount of semi-finished material in stock for quick turnaround. Ta bars are also available in alloyed materials, such as tantalum tungsten alloy Ta-10W

|

Material |

R05200, Electron beam or vacuum-arc cast tantalum |

|

|

R05400, Sintered tantalum |

|

Standard |

ASTM B365, Tantalum and Tantalum Alloy Rod and Wire |

|

|

ASTM B708, Tantalum and Tantalum Alloy Plate, Sheet, and Strip |

|

|

ASTM F560, Unalloyed Tantalum for Surgical Implant Applications |

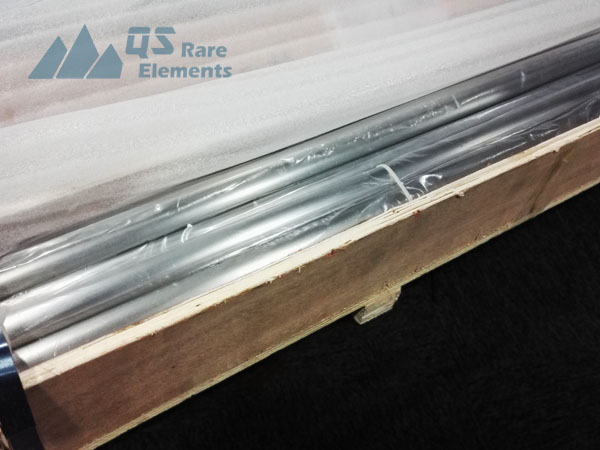

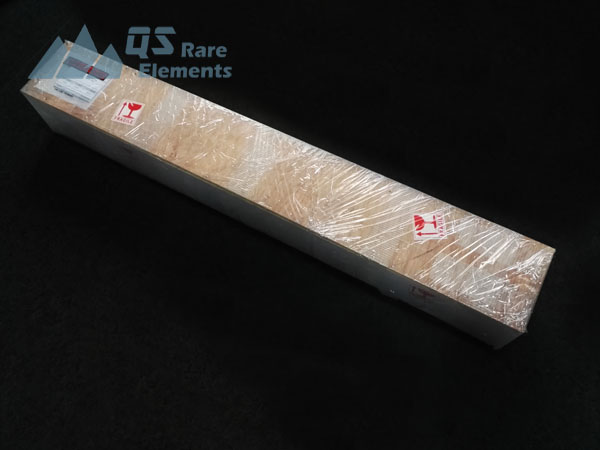

Tantalum (Ta) bars packaging

Tantalum is stable in air and packed without vacuum seal, unless requested. Wooden crater is applied when the cargo is over weight.

*Mill report available for our tantalum bars.

Related Product

Tungsten Heavy Metal Alloy (W-Ni-Fe) Bucking Bar